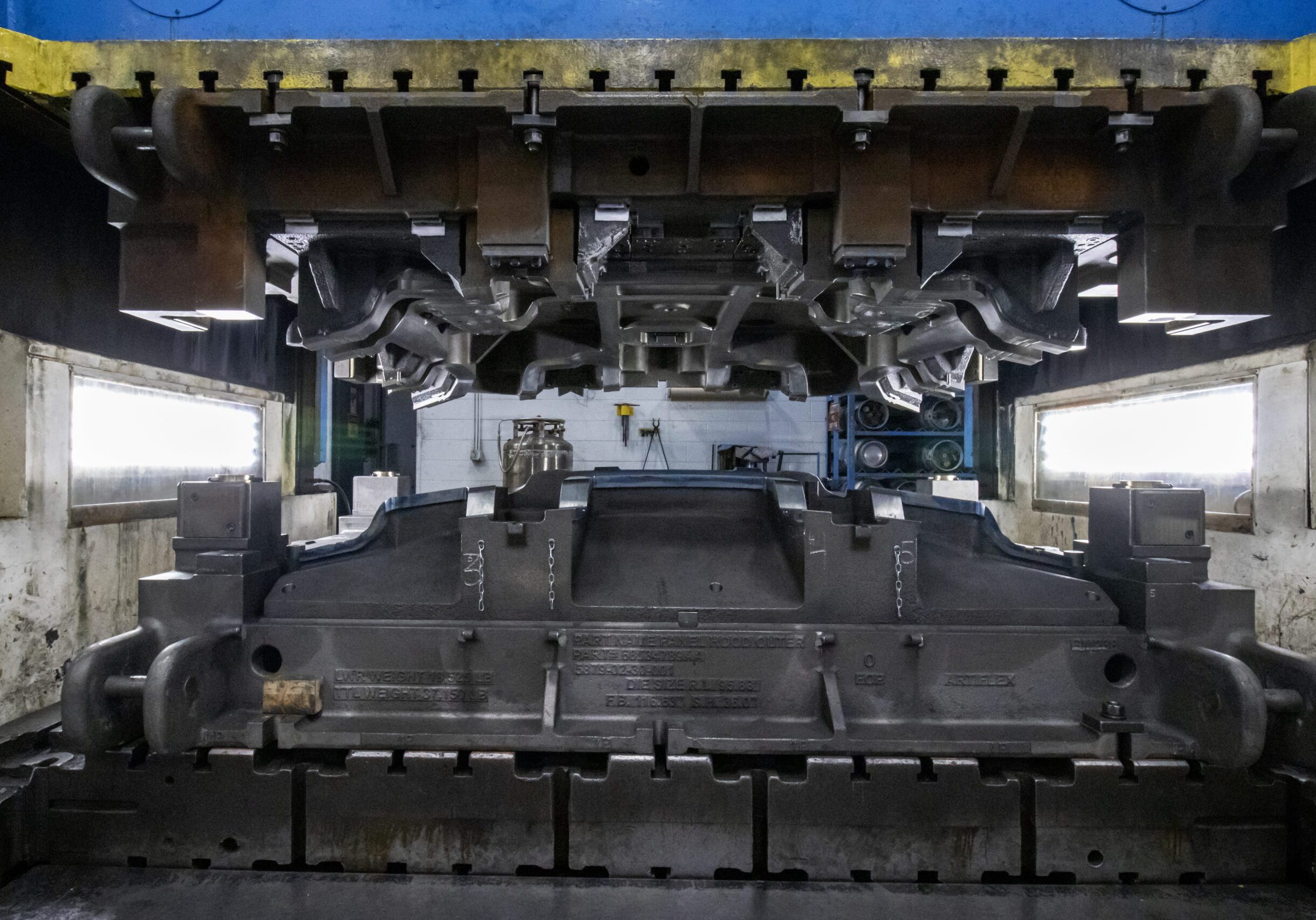

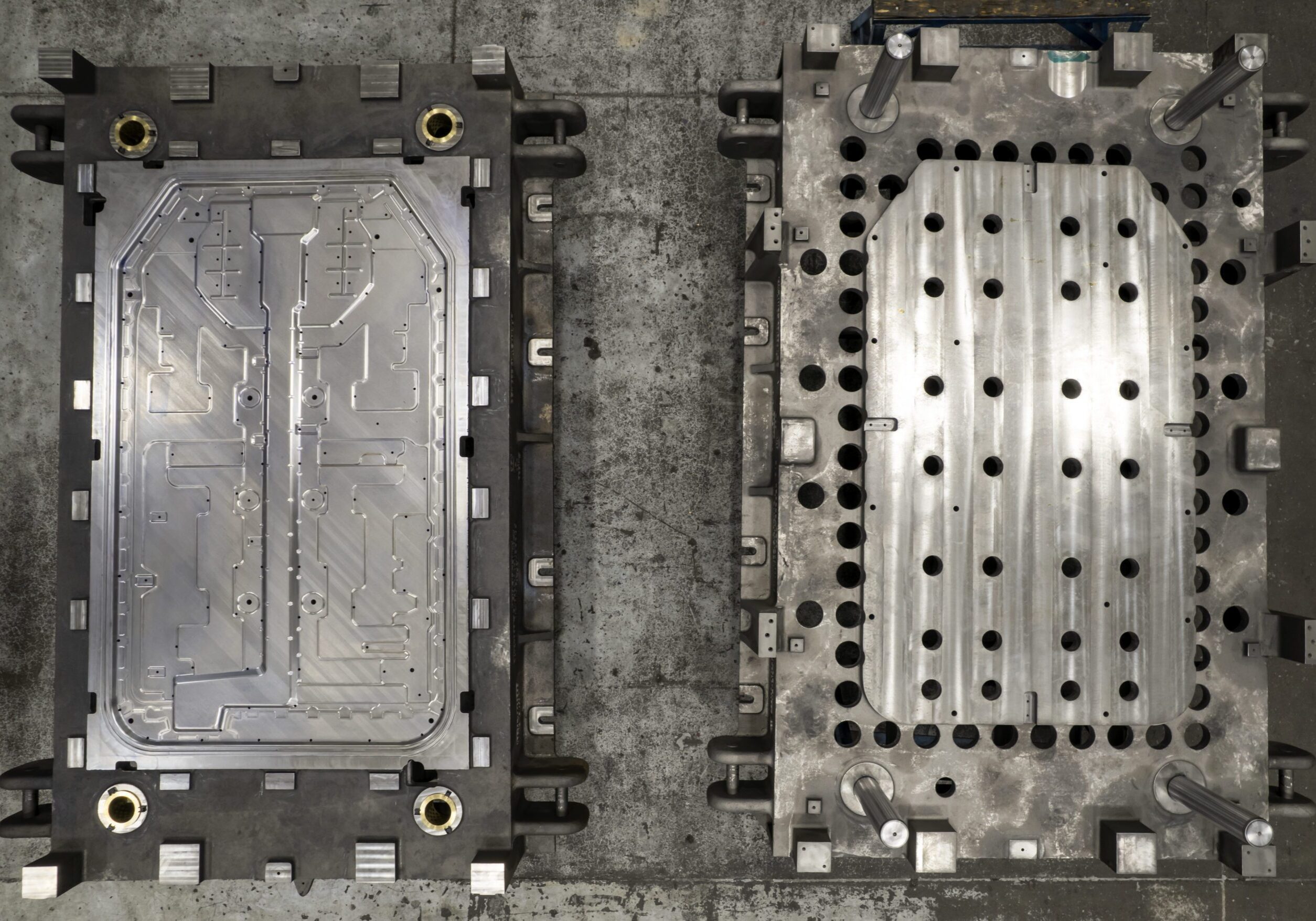

Flexible Dies

Based on customer demand, we can design tooling that allows for flexible stamping using the same set of tooling.

Experienced

Artiflex provides dies for a range of applications, from service needs to EVs.

Laser Technology

Innovative laser technology allows us to provide flexible tooling solutions to meet customer quality standards.

Equipment At This Location

Wire EDM

2 – Charmilles Robofil 290 4-Axis CNC Wire EDM's 15.7" X, 9.8" Y, 7.9" Z, 5.7” U, 9.8” V Travel

- Uni-Graphics (22 Seats)

- Catia v5 R19 (1 Seat)

- SDRC (1 Seat)

- Rhinoceros Software (1 Seat)

- Work NC (5 Seats)

- Lemoine (9 Seats)

- VisView (Shop Floor Viewing Software) (9 Seats)

- Auto-Form Simulation Software (2 Seats)

- OmniMesh Morphing Software (1 Seat)

- Rapid Form Software (1 Seat)

- 2 - 30/10 Ton Overhead Cranes

- 1 - 25 Ton Overhead Crane

- 5 - 20 Ton Overhead Cranes

- 1 - 20/5 Ton Overhead Crane

- 1 - 15 Ton Overhead Crane

- 4 - 10 Ton Overhead Cranes

- 2 - Allis Chalmers 12,000 LB LP Gas Forklift

- 1 - Allis Chalmers 10,000 LB LP Gas Forklift

- 1 - Linde 8,000 LB LP Gas Forklift

- 1 - Yale 4,750 LB LP Gas Forklift

- 1 - UNI Carriers 4000 LB Electric Forklift

- 1 - Automatic Transportation Company 20,000 LB.

- Electric Die Cart

1 – ITP CMM with PCDMIS

- Renishaw PH10M Probe

- 240” x 96” Table

- 192” X, 86” Y, 120” Z Travel

1 – DEO Vento CMM with PCDMIS

- Renishaw PH10T Probe

- 187” x 65” Table

- 150” X, 55” Y, 75” Z Travel

1 – API Radian Blue Light Scanner and Laser Tracker

1 – CogniTens Optigo White Light Scanner

1 – Creaform Red Light Scanning Systems

2 – Rockwell Hardness Tester

1 – Olsen Ductility Tester

1 – Ultrasonic Tester

Mill Software:

5 - Work NC Seats

- 3 – Full Seats

- 1 – 3X Seat

- 1 – 2D Seat

- 1 – Advance Toolform Seat

1 – Sigma SDV-4224 CNC Bridge Mill

- 6,000 RPM

- 86” x 157” Table

- 98” Between the Columns

- 165” X, 94” Y, 30” Z Travel

1 – Pratt & Whitney CNC Vertical Mill

- 3,000 RPM

- 63” x 152” Table

- 120” X, 72” Y, 30” Z Travel

1 – Toshiba CNC Bridge Mill

- 10,000 RPM

- 70” x 74” T-Slotted Power Feed Table

- 83” Between the Columns

- 88” X, 55” Y, 28” Z Travel

1 – Toyoda LB321 Bridge 3+2 Bridge Mill

- 6,000 RPM

- 80” X 118” Table

- 90” Between the Columns

- 120.5” X, 110.2” Y, 55.1” Z Travel

1 – Shibaura MPJ-2640M 3+2 Bridge Mill

- 10,000 RPM

- 78” x 157” Table

- 102” Between the Columns

- 177” X, 118” Y, 68.3” Z Travel

1 – LeBlond Makino CNC Vertical Mill

- 6,000 RPM

- 31” x 58” Table

- 80” X, 39.5" Y, 27.5" Z Travel

1 – SNK Bridge Mill

- 2,500 RPM

- 55” x 110” Table

- 66” Between the Columns

- 80” X, 39.5" Y, 27.5" Z Travel