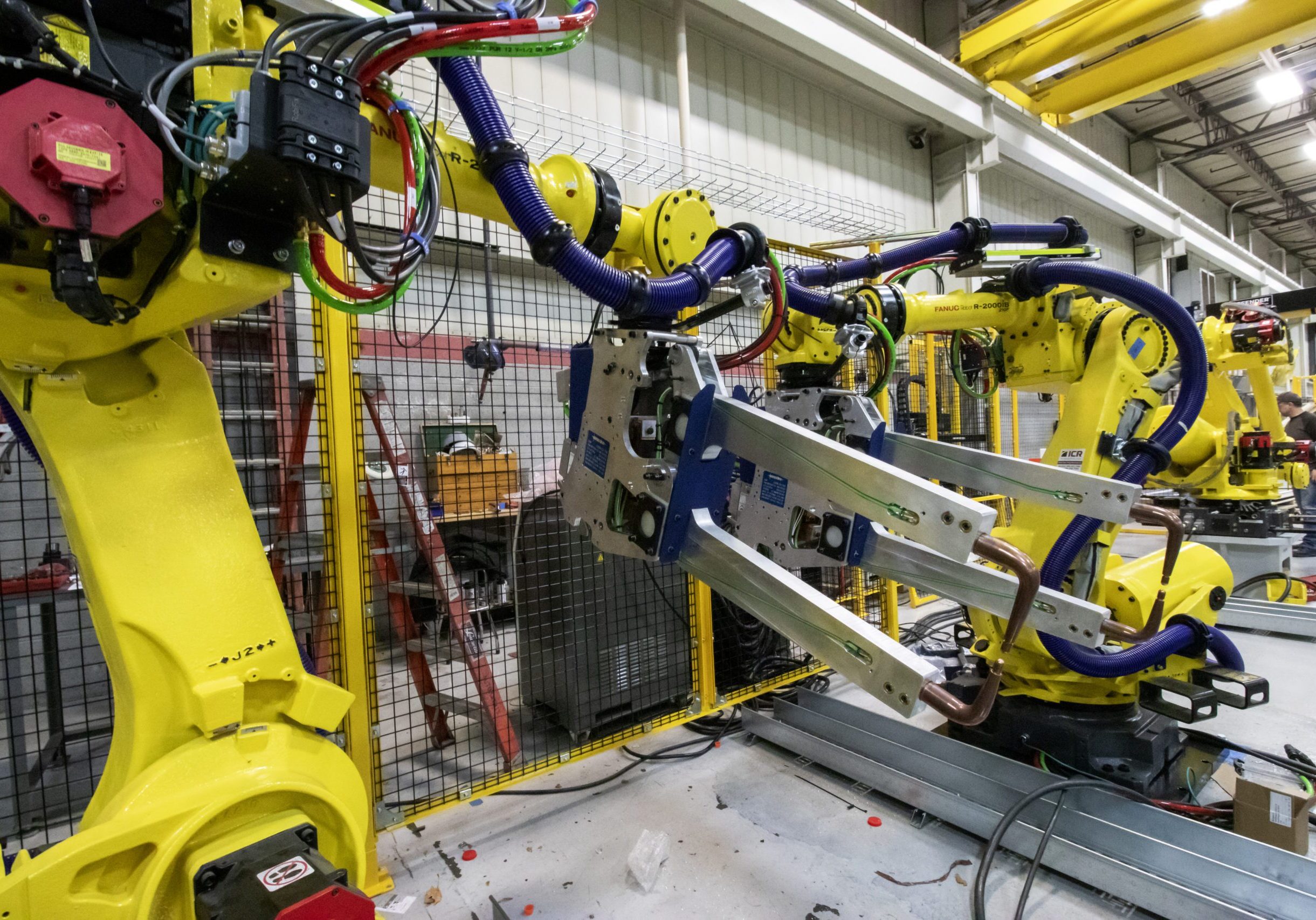

Spot Welding

- Aluminum and steel robotic spot welding.

- Fixed gun welding applications and machines.

- Weld-thru adhesives, and automated inspection

- SPR (self-piercing rivets), FDS (Flow-Drilled Screws) and TOX joining.

MIG Welding

- Aluminum and steel MIG and TIG processes.

- CMT (Cold Metal Transfer) welding.

- Robotic and coordinated motion processing.

- Lincoln, Miller, and Fronius

Aluminum

- Aluminum extrusion forming, punching, saw cutting, and machining.

- Fastener installation (rivnut, clinch nuts, etc).

- Welding and other joining systems.

- Deburring, inspection, and part marking.

Equipment At This Location

- SolidWorks Design (16 seats)

- AutoCad Electrical (4 seats)

- Rockwell Automation - Studio5000 (10 seats)

- GE Proficy – (4 seats)

- Fanuc Roboguide offline simulation software

- ABB Robostudio seats for programming/sim

- Welding (Spot, MIG, Laser, Friction-Stir) tooling and capital equipment

- Closures hemming (Robotic Roller, Table-Top, and Press Hemming).

- Fastener installation in sheet metal.

- Adhesives and bonding.

- Joining (SPR, FDS, Clinch)

- Aluminum extrusion value-add processes.

- Assembly and inspection (pressing, screw driving, leak testing)

- Machining and metal forming.

- Roll form line components.

- Automotive (OEM and Tier 1/2 supply).

- Agriculture

- Furniture

- Medical Device

- Food Processing/Storage

- General Manufacturing

- 45,000 sq ft facility

- (2) 10 ton cranes

- (1) 5 ton crane – all 3 travel over drive through bay

- Power – 8,700 amps

- (4) knee mills, lathe

- (2) surface grinders, vertical band saw, roll-in band saw, powered break press, manual brake press, shear, belt sander

- (2) drill presses, radial arm drill